Producing very bright sub-micrometer beams of high-energy X-rays - Observation of microareas inside thick metal samples has become possible -(Press Release)

- Release Date

- 22 Feb, 2024

- BL05XU (R&D-ID I)

22 February 2024

JASRI

RIKEN

A collaborative research group led by Takahisa Koyama (Senior Scientist), Hirokatsu Yumoto (Senior Scientist), and Haruhiko Ohashi (Director) of the Beamline Division, Japan Synchrotron Radiation Research Institute (JASRI), and Makina Yabashi (Group Director) of the SACLA Beam Line Research and Development Group, RIKEN SPring-8 Center, has developed multilayer focusing mirrors (reflecting mirrors) that focus high-energy X-rays of 100 keV into a sub-micrometer range at the BL05XU beamline of a large synchrotron radiation facility, SPring-8. One of the features of SPring-8 is the availability of bright high-energy X-rays. Internal structures of thick metal samples can be observed in detail if high-energy X-rays are focused into small beams. However, there has been no high-throughput optical element that can focus high-energy X-rays into small beams. The research group developed high-throughput multilayer focusing mirrors and succeeded in effectively focusing high-energy X-rays into a sub-micrometer range. The focused beams realized in this research have been already used in the observation of the internal structures of devices enclosed in metal cases and the local structures of thick steel materials. Their research achievements were published in the online version of an international scientific journal, the Journal of Synchrotron Radiation, on Thursday, 22 February 2024. 【Publication】 |

Fig. 1 Photograph and schematic of the developed 100 keV multilayer focusing mirrors

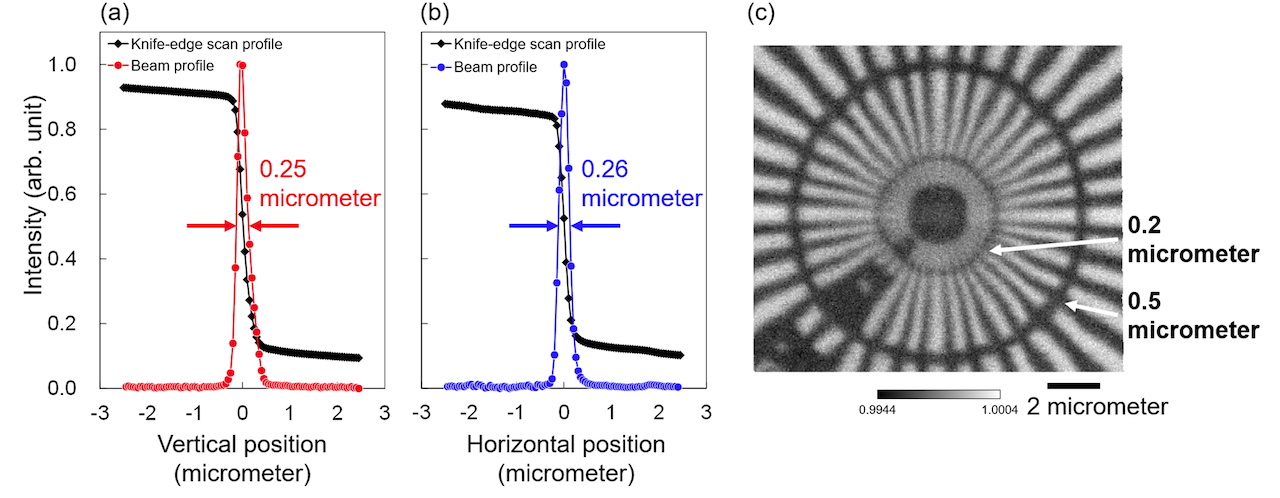

Fig. 2 Measured focusing beam size and observation result of test chart

|

《Contact》 |

- Previous Article

- A new technique for exclusive visualization of platinum particles in catalysts used in fuel cells(Press Release)

- Current article

- Producing very bright sub-micrometer beams of high-energy X-rays - Observation of microareas inside thick metal samples has become possible -(Press Release)