Birth of X-ray Beams of Nanometer Size, World’s Smallest Diameter - Extraordinary beam enabling ultrahigh resolution

Triggered by development of X-ray free electron laser

The completion of the X-ray free electron laser (XFEL) facilities, which are under construction in the SPring-8 campus, is impending. XFEL refers to an intense X-ray laser, in which the wavelength and positions of crests and troughs are completely aligned (in phase), similar to visible laser light. The brilliance of XFEL is a billionfold higher than that of the synchrotron radiation produced at SPring-8 (calculated using the maximum brilliance as a reference), and the light-emitting time is in the femtosecond order (1 femtosecond is 10-15 s, during which light travels only 0.003 mm). Even the hard X-rays (X-rays with much shorter wavelength and higher energy than those of general X-rays) produced at SPring-8 are extraordinarily bright; you can easily imagine how intense and bright XFEL is. It is expected that the instantaneous movement of electrons, the speed of which is close to the speed of light, can be recorded and analyzed in detail using XFEL because of their femtosecond-order pulse width (emission duration). Although XFEL itself is effective, to further increase its brilliance and use it in various applied research studies, a reflecting mirror is required to control the beam depending on the purpose. Tetsuya Ishikawa, Director of RIKEN SPring-8 Center and also the project leader of the SPring-8 Joint Project for XFEL, and his colleagues, jointly with the group of Professor Kazuto Yamauchi of the Graduate School of Engineering, Osaka University, who leads the world in high-precision surface machining technology, carried out the preliminary measurement of the precision of the reflecting mirror used for controlling X-rays with an aligned phase like XFEL. In the preliminary measurement, the 1-km-long BL29XU beamline, which can produce the most phase-aligned hard X-rays among all the beams at SPring-8, was used because the XFEL facilities are still under construction.

Start from the development of high-performance shape-changeable mirror

When spatially concentrated X-rays emitted by a strong radiation source travel straight for a long distance, the exterior of the beams (bundle of rays) is diffused, but reasonably phase-aligned beams remain near the centerline of the beams. When only such interior beams extracted from the bundle of rays are reflected on a plane mirror, which is considered to be completely precise, a spotted pattern called speckle surprisingly appears in the light figure. In the speckle phenomenon, a bundle of rays with aligned phase is diffusely reflected on each point on a mirror surface, inducing a slight shift in phase between the light waves included in the bundle of rays, and the intensity of the light waves is increased or decreased. Speckle is proof that the mirror surface is not completely flat. The plane mirror was fabricated by elastic emission machining (EEM; ultrahigh-precision plane machining by chemical reaction between microparticles and the surface of a workpiece), which can correct even the unevenness of a constituting molecule of the mirror surface. The reason for inducing speckle in such a plane mirror was that there were subtle distortions that cannot be recognized using the conventional beams and measurement methods. The high-precision measurement technology at SPring-8 and measured data were transferred to and applied to the machining technique adopted at Osaka University, enabling the fabrication of a plane reflecting mirror without inducing speckle. Moreover, by further improving the measurement technology developed, the fabrication of an aspherical reflecting mirror, such as an elliptical mirror explained later, became possible.

Fabrication of ultrahigh-precision K-B mirror

To directly observe the steric structure of nanometer-size protein molecules and spatial structure of angstrom-size (1×10-7 mm) hydrogen atoms, bright beams with a wavelength comparable to or much smaller than the target are indispensable. Investigation of a specimen using dark beams with a long wavelength is similar to measuring the diameter of a thin hair at the leg tip of an ant in a dark hole using a ruler marked in centimeters in dim light. The wavelengths of hard X-ray synchrotron radiation emitted by a 1-km-long beamline and XFEL are sufficiently short and have high penetrating power; however, the intensity (photon density) should be increased further. Director Ishikawa, Professor Yamauchi, and their colleagues considered that they can overcome this problem when the new mirror fabrication technique and mirror surface control technology are applied.

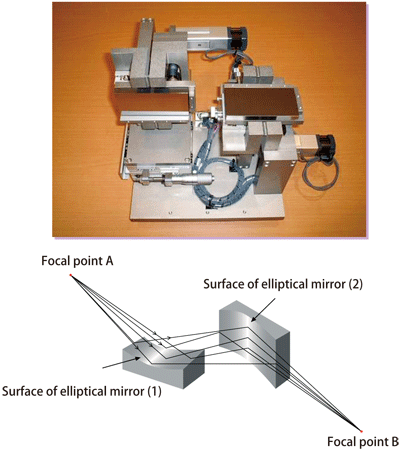

The diameter of the bundle of rays should be as small as possible to increase the photon density of the beams. A similar method can be used by which the brilliance is increased by concentrating sunlight in the vicinity of a focal point using a convex lens. In this study, a special reflecting mirror, called a Kirkpatrick-Baez mirror (K-B mirror), was used instead of a convex lens. For a elliptical mirror with spheroid shape (a solid obtained when an ellipse graph is rotated around the X-axis on which two focal points exist), the beam from one of the focal points is reflected on the mirror surface and concentrated on the other focal point. This principle is effectively applied in the K-B mirror. In practice, instead of a complete elliptical mirror, a pair of two reflecting mirrors, composed of two mirror surfaces with a small curvature cut from a elliptical mirror, was used (Fig. 1). The all-reflective elliptical mirror developed in this study was a reflecting mirror having a surface of ultrahigh-precision long ellipse with dents of a few micrometers (μm = 10-3 mm) from the horizontal plane with respect to 10 cm in the horizontal direction even at the most concave position. This structure was adopted because a long elliptical mirror with a long distance between two focal points can suppress light diffusion. This mirror was only realized using the state-of-the-art measurement technology of SPring-8 and the excellent machining control technology of Osaka University.

Fig. 1 K-B mirror

The beams irradiated from point A, a focal point of the elliptical mirror (1), are reflected on the surface of the mirror (1) and concentrated in the vertical direction. Then, the beams are reflected on the surface of the elliptical mirror (2) and further concentrated in the horizontal direction. Finally, the beams are concentrated at point B, a focal point of the elliptical mirror (2).

Birth of world’s smallest-diameter beam

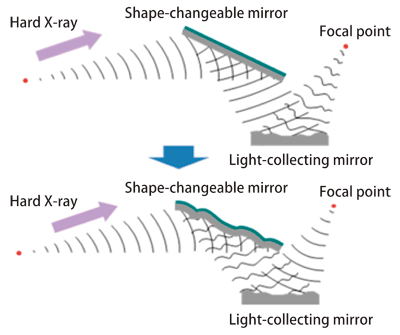

The beams irradiated from point A (focal point of the elliptical mirror (1)) as shown in Fig. 1 (below) are reflected on the surface of the elliptical mirror (1) and concentrated in the vertical direction. Then, the beams are reflected on the surface of the elliptical mirror (2) and concentrated in the horizontal direction. Finally, the beams become extremely bright and narrowed, and are concentrated at point B (focal point of the elliptical mirror (2)). Assuming the distance between the light source and point A of the light-collecting mirror system as 1 km and that between points A and B as 10 cm, the beam diameter is narrowed to 1/10,000 on the basis of a principle that is almost similar to the lens equation. However, additional devices are required to generate ultrahigh-brilliance beams of less than 10 nm diameter. When the hard X-rays from the 1-km-long BL29XU beamline with the most aligned phase in the world are directly irradiated on a K-B mirror, a subtle error on the elliptical mirror surface causes a slight disturbance of the wave, and sufficient concentration of the beams is impossible. Therefore, the members of the research group developed a corrective shape-changeable mirror, the shape of which can be controlled with the accuracy of 0.1 nm, and placed it before the light-collecting mirror to correct the phase of the incident light beforehand (Fig. 2). As a result, they succeeded in generating the high-brilliance X-ray beams of 7 nm diameter, which is comparable to the diffraction limit (theoretical limit of diameter when light is concentrated), for the first time in the world (Fig. 3). The development of an X-ray microscope with nanometer-level resolution (discrimination capability), which can be used to directly observe the steric structures of molecules and atoms, will be possible if ultrahigh-brilliance X-ray beams are generated by combining XFEL and the above light collection technique. Director Ishikawa said, “If the diameter of the beam can be reduced by one digit, electrons and positrons can be generated by eliminating the vacuum. When an electron and a positron collide, they disappear after emitting light. We are trying to induce a phenomenon opposite to this.”

Fig. 2 Role of shape-changeable mirror and formation of X-ray nanobeams using the shape-changeable mirror

The errors on the light-collecting mirror are corrected by slightly changing the shape of the surface of the shape-changeable mirror depending on the situation.

Fig. 3 X-ray nanobeam realized using the developed X-ray light-collecting optical system

The generation of X-ray beams of 7 nm diameter, which is smaller than the conventional 10 nm, was successful for the first time in the world. The figure indicates the intensity distribution of the beam at the focal point after correction (refer to point B in Fig. 1).

Inquiring mind supports foundation of optical science

Director Ishikawa was raised on the Izu Peninsula, which is richly endowed with nature, and was a boy full of curiosity. When he was a senior high school student, he was inspired by a speech by the late Hitoshi Takeuchi, a geophysicist, and became interested in wave phenomena; he then majored in applied physics at the University of Tokyo. He said, “The lectures on topics other than wave function were readily understandable, but the wave function that explains various complicated phenomena of light was difficult for me then.” Therefore, he decided to embark on the research of wave function and related optical science. The interviewer felt his firm conviction as a scientist, i.e., tackling difficult problems head on as a scientist, behind his gentle face. He moved to SPring-8 after leaving the post of associate professor at the University of Tokyo, because, the interviewer thought, he hoped to place himself in a state-of-the-art research environment and carry out research that can lead the world. Director Ishikawa said, “If we can generate a “high-quality light” that can support the foundation of optical science, applied research will naturally follow. I am now devoting myself to generating such a light. Ever advancing optical science will never be outdated,” his eyes shining just like those of a curious boy. His last words to young researchers urging them to read between the lines when reading papers were highly motivating and impressive.

Interview and original text by Narichika Honda

This article was summarized following an interview with Tetsuya Ishikawa, Director of RIKEN SPring-8 Center.